Consulting and Planning for Automatization

with Assembling and Material Flow Planning

Customer specific tasks in most cases require special or adjusted solutions for the individual task and the company. Therefore we support our customers by previous consulting and planning as a team to make sure to find together the perfect solution.

This process and planning can be done independent without a commitment for a implementation of the project. This step can be seen as verification of feasibility, capital expanditure and profitability.

Factory Planning, Logistic and Projectmanagement

The improvement of profitability and flexibility of our customers is our highest goal considering the entirely factory planning with logistics, material flow, material handling technology and workplace configuration. Years of experience and the use of latest technologies makes it possible for us to provide innovative and economic solutions.

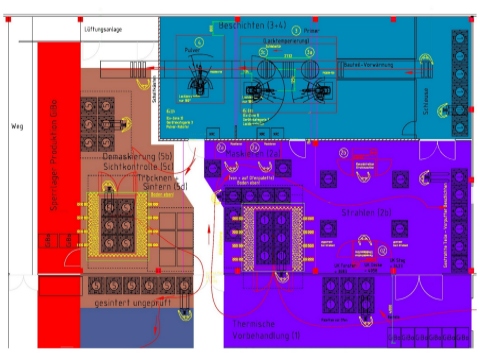

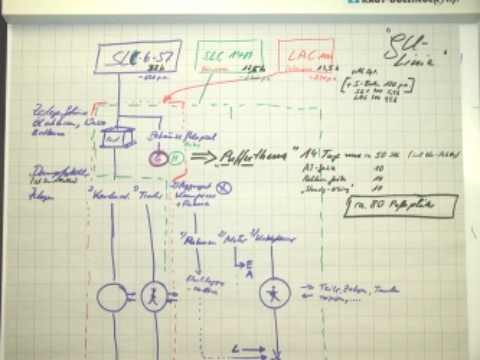

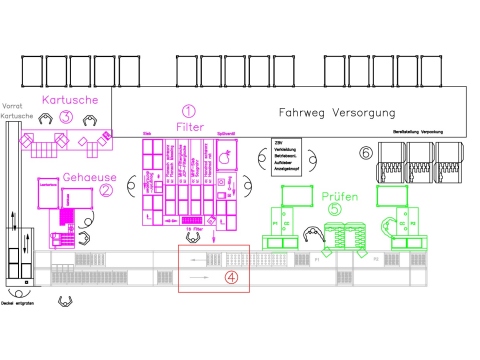

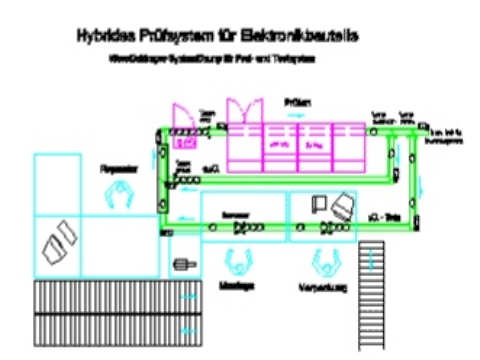

Project and Process Planning

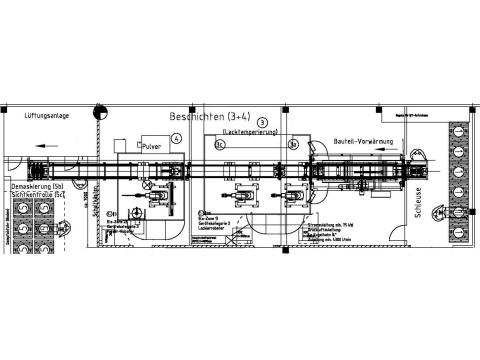

With the projecting of complete systems specific sections get coordinated and the overvie plan will be documented as a layout.

the layout defines different segments and includes measures and intersections. Those will be verfified by the customer.

Design and Development

Customer sepcific machines and systems will be elaborated contructively after completion of projecting and layout approval. requirements like functional relibility, maintenance accessability and ergonomics will be determined already in the phase of development and are therefore coordinated with the customer.

After discussing and approving the draft the design documents will be elaborated more into detail in mechanics and electics and approved for the production and assembly. At the end the documentation will be prepared and completed.

Manufacturing, Assembly and Commissioning

Special machines, automatic machines and plants are manufactured, assembled and commissioned in our factory. In the test/trial/acceptance operation, the functions, properties, performance etc. are checked in our factory together with the customer, and a trial run is carried out with customer personnel.

The simultaneous instruction and training of the future plant operators as well as the maintenance and service personnel shortens the start-up phase in your company.

Maintenance and Service

Our customers often produce in several shifts, so it goes without saying that you can reach us even after normal office working hours and do not have to leave your current, urgent problem on the answering machine. Do not wait until a problem occurs – use our service.

Preventive maintenance and service by the specialist increases reliability and availability. We are happy to carry out this maintenance and service work during production-free periods.

We always have standard spare parts in stock.

For project-specific parts, we will be happy to put together a spare parts package for you.